Feb 2009, Bay Area Choti

slot blog link to the build thread...

... I began a new project just for fun: "A Bay Area Choti"! I have

seen many and held a few in my hands. They are simple, lightweight and built

to go fast! In fact, I believe they were the fastest slot cars ever in 1968

and the forerunner of the modern Open Wing Car class. But, most of you already

know this.

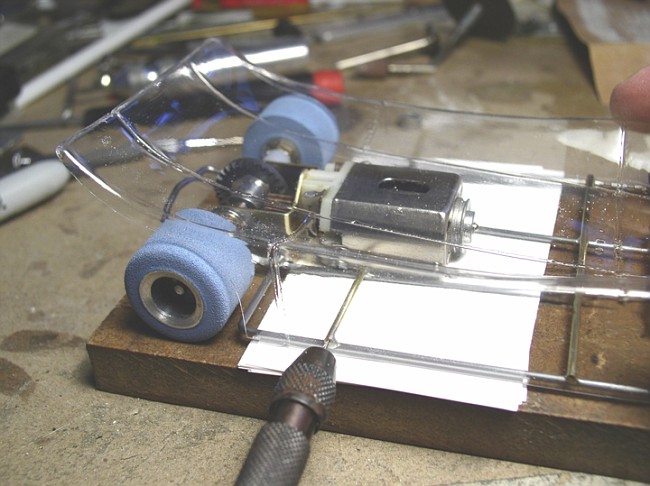

I choose to keep the design very vintage and simple. No ball bearing races,

no extra weight and no fancy wire bending or polishing. I am building a replica

of something from the era to see how well these little rockets actually ran.

This chassis weighs about 7oz. or 20g. It is a direct replica of what was being built and run in and around the Bay Area of San Francisco.

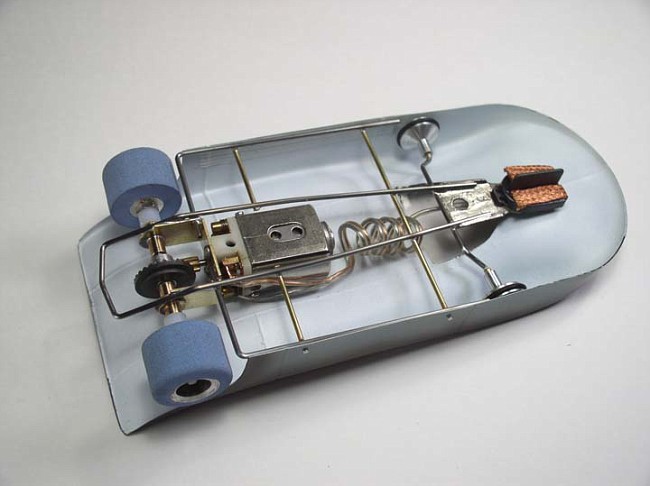

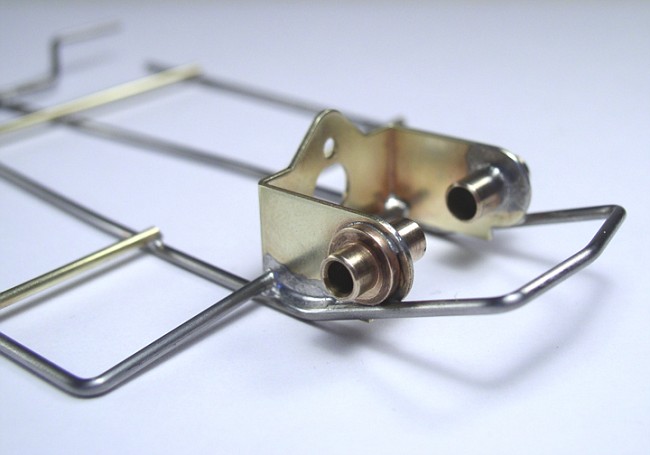

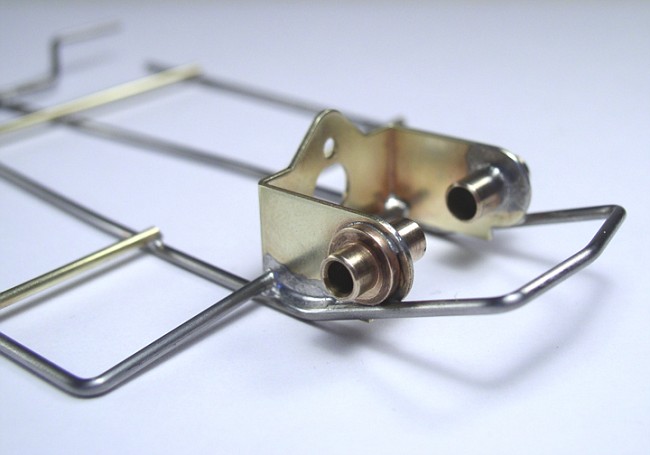

The rear oilites are vintage pieces and the latest purchase which completed

the search for chassis parts. The bearing surface is only 1/8" on the outside

end. The length inside provides a surface tension well for storing vast qualities

of lubrication during operation and centers the ring gear.

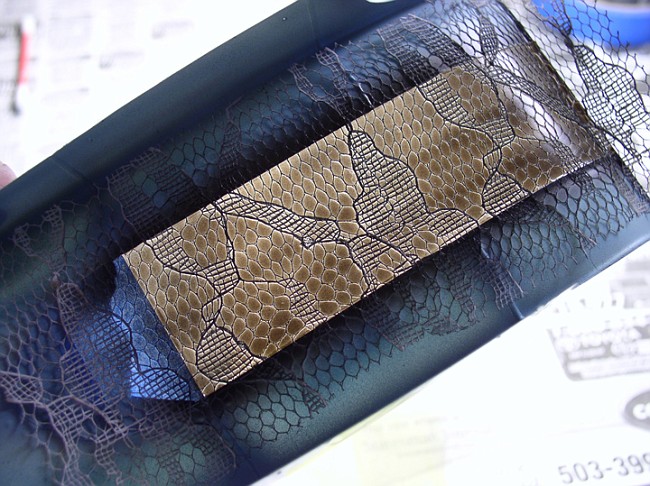

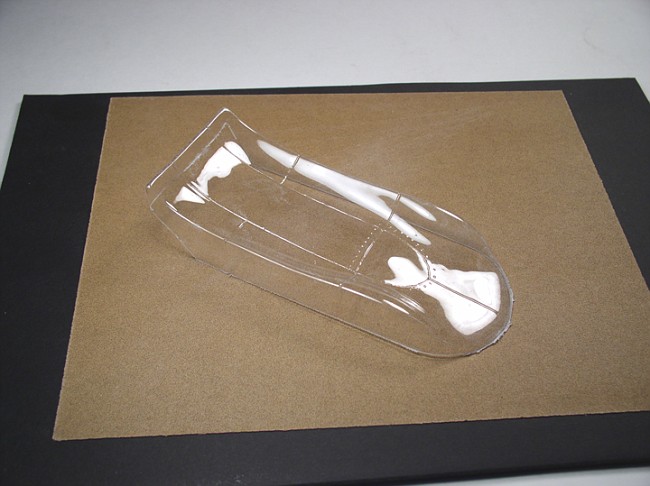

Some say that the body should be painted prior to trimming so that the top

surface remains over-spray free. If you are painting with rattle cans then it

makes sense to cut later... but as you will see, with an airbrush, masking and

low air-pressure can take care of any over-spray. Plus, Testors airbrush thinner

is good enough and strong enough to clean off any Pactra Lacquer paint over-spray.

Besides, I like being able to see through the body for tight fitting and mounting.

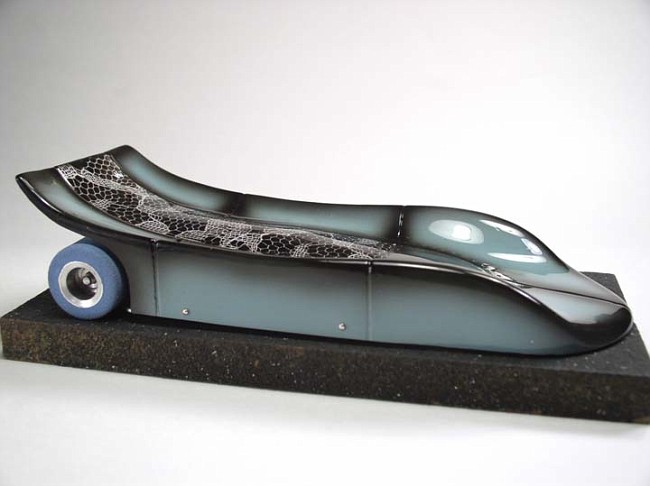

First step is sanding the bottom edge smooth and flat.

I do this with a piece of 220 grit dry sand paper glued to a piece of foam core board.

I test fit over and over along with trimming of the rear wheel openings. Then when I am happy, I drill the pin holes with a pinvise. Drilling leaves no tapered residue on the inside of the body like simply poking a pin through will. A stack of business cards provide support for the body front and rear. (One card equals about .010)

Very important to prep the body correctly so the paint will stick. Roughing

up the inner surface is important but using too rough a grit sandpaper or steel

wool will have ill effects should the paint be thinned too much. Lacquer thinner

applied “neat” on lexan, PETG or Butyrate will leave the surface

damaged. Paint sprayed too HOT (Too much thinner vs paint) will have the same

effect.

Very important to find the right consistency and air pressure!

I use 000 steel wool to rough up the inside of the body after masking the windows. Then a clean paper towel with 91% Isopropyl Alcohol is used to wipe out the inside. This will ensure that no fingerprints or solvents are left behind. (Steel Wool is treated so that it will not rust so might leave something behind!)